Standardized Production Process of Jiayue Adult Pull-Up Pants!

As global aging accelerates and consumers increasingly seek comfort and superior absorbency, the demand for adult pull-up pants in the incontinence care sector continues to rise. Jiayue, a professional manufacturer specializing in disposable hygiene products for over a decade, has earned the trust of customers worldwide with its commitment to high quality. Now, let’s step into Jiayue’s modern factory and explore each critical stage from raw materials to finished adult pull-up pants.

1、Raw Material Preparation:Before production begins, factory staff prepare all necessary raw materials according to the work order, including fluff pulp, SAP (super absorbent polymer), non-woven fabrics, backsheet films, and more—laying the groundwork for efficient production.

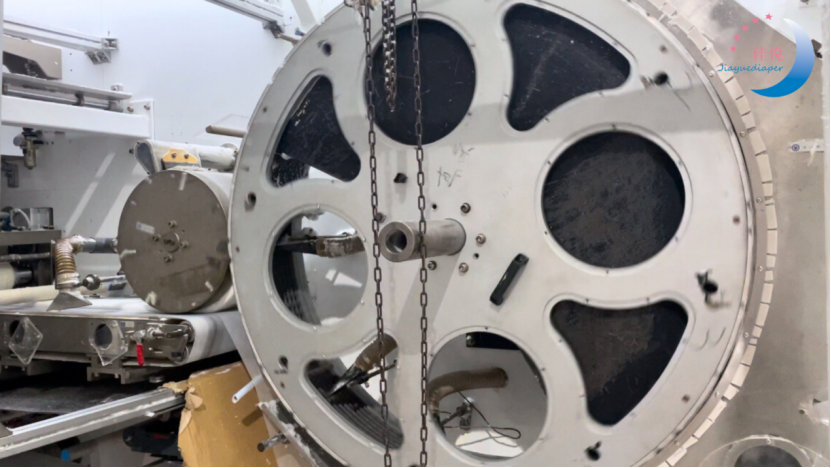

2、Fluff pulp mincing - SAP uniform mixing - Fluff pulp cotton core flattening and shearing. Jiayue uses automated equipment to defibrate high-quality fluff pulp and evenly mix it with imported SAP. The blended material is then flattened and cut to form a dense, high-absorbency core structure.

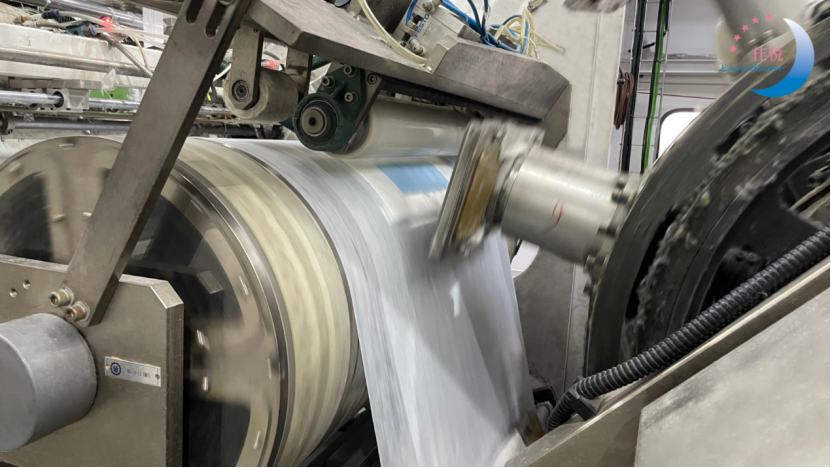

3、Top Sheet Compound.The shaped absorbent core is wrapped with top and bottom non-woven layers using a lamination unit. This step stabilizes the core and prevents shifting, laying the foundation for a comfortable and secure fit.

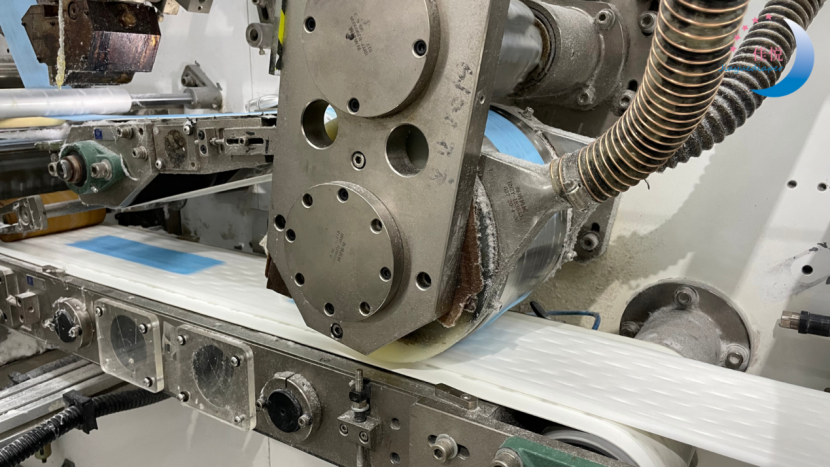

4、Simultaneous:Back Sheet Compound-Wetness indicator-Spandex-Glue bonding.This multi-step process includes: Wetness Indicator: A color-changing strip is added to the backsheet for timely replacement alerts.Spandex Threads: Integrated into the waist area to enhance elasticity and leak prevention.Adhesive Bonding: All layers are bonded using hot melt adhesives to ensure structural integrity and durability.

5、360° Waist bonding:Using heat sealing, a full 360° elastic waistband is formed, delivering a snug, leak-proof fit and easy pull-on/pull-off convenience.

6、Finished Product:Finished diaper pieces are automatically stacked by a stacker, ready for quality inspection to ensure every unit meets strict standards.

7、Inner and Outer Packaging.Qualified pieces are grouped and packed into inner bags, sealed to protect against moisture and contamination during storage and transportation.